Product Description

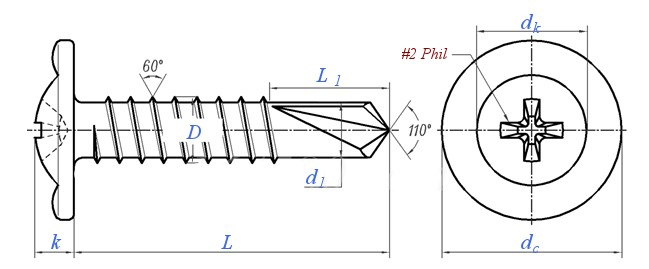

| Material | C1022A |

| Diamter | 3.9mm/4.2mm/4.8mm(#7/#8/#10) |

| Length | 13mm--50mm(1/2”-2”) |

| Finish | Zinc plated |

| Head type | wafer head |

| Thread | Fine |

| Point | drilling point/sharp point |

Packing

1. Bulk: 10000pcs/20kgs/25kgs in a plastic bag, then in carton, in pallet.

2. 200/300/500/1000pieces in a small box, then in carton,without pallet.

3. 200/300/500/1000pieces in a small box, then in carton, with pallet.

4. According to your request.

All packing can be done as per customer!

Head Self Tapping Screw

Introduce:

The importance of choosing the right screws in construction and woodworking projects cannot be overstated. In recent years, truss self drilling screws and modified truss head screws have gained tremendous attention due to their enhanced performance and versatility. We will explore the various applications and benefits of truss self-drilling screws, focusing specifically on the improved truss head screw variant.

The power of truss self-drilling screws:

1. Enhanced drilling capabilities: Truss self-drilling screws, as the name suggests, require no pre-drilling or pre-tapping holes. Their tips and sharp wings can easily penetrate wood, metal or plastic, significantly saving time and eliminating the risk of splitting.

2. Reliable clamping: The specially designed wings or threads on truss self-drilling screws provide excellent clamping force by firmly clamping the material being drilled. This feature, combined with improved truss heads, ensures greater stability in applications where strong connections are critical.

Explore improved round head screws:

1. Increased load-bearing capacity: The unique feature of modified round head screws is their larger head, which distributes the load over a wider surface area. This feature significantly enhances its load-bearing capacity, making it suitable for heavy-duty applications such as frames and decks.

2. Countersink capability: Improved round head screws also provide valuable countersink capability. This keeps the screw flush with the material surface, preventing snagging, reducing time-consuming and complicated steps like filling, and providing a clean, professional finish.

Application of truss self-drilling screws:

1. Construction Projects: Truss self-drilling screws, especially the modified truss head variant, are the first choice for construction applications such as framing, roofing and installing drywall. Their ability to drill, clamp and distribute loads efficiently makes them ideal for these demanding projects.

2. Woodworking: Kitchens, furniture making, and cabinets benefit greatly from the use of self-drilling screws for trusses. Easy installation and secure grip ensure the final product is strong, durable, and able to withstand daily use.

3. Metalworking: Truss self-drilling screws can also be used for metalworking tasks. Whether fastening metal panels or fastening electrical boxes to metal studs, their drilling and clamping capabilities provide reliable fixation in such projects.

In conclusion:

In summary, truss self-drilling screws, especially the improved truss head screw variant, offer a viable solution that combines efficiency, versatility and strength. Their ability to drill, clamp and distribute loads makes them indispensable in a variety of construction, woodworking and metalworking projects. As with any construction material or tool, it is critical to select the appropriate screw type based on specific project requirements.

Whether you are a professional contractor, a DIY enthusiast, or someone embarking on a home project, considering the benefits of truss self-drilling screws and modified truss head screws can improve the quality and efficiency of your work. Embrace the power of these screws and experience the ease and reliability they bring to your projects.

| Specifications | 4.2 | |

| D | 4-4.3 | |

| P | 1.4 | |

| dc | 10.2-11.4 | |

| K | 2-2.5 | |

| dk | reference value | 7 |

| L1 | reference value | 5 |

| d1 | reference value | 3.2 |

| Slot number | 2 | |

FAQ

1. What is your main products?

Drywall screws, self tapping screws, self driling screws, chipboard screws, blind rivets, common nails, concrete nails..etc

2. What is your delivery time?

It depands, usually it will take around 20 days for 1x20ft. and of course we will finish it within 10 days once we have stock in our warehouse.

3. What is your payment term?

T/T. 30% prepayment in advance and 70% before loading container or as per both side agreement.

4. How is your quality? And what if we don't satisfied your quanlity?

We produce your order strictly by your request. If the quality was not acceptable, we will refund to you.

Company information

Our factory was built in 2006 and we already in this filed of more than 8 years producing, so we promise your our best quality and good service.

We have 50 sets cold heading machine and 35 sets thread rolling machines and 15 sets drilling machines, so we will promise you the leading time will be assured. pls do not worry about this.

Sincerely welcome your visiting our factory and inquiry us, thanks.

Your precious comments and feedback will be highly appreciated by us.